Detailed explanation of copper mining methods

Detailed explanation of copper mining methods

Blog Article

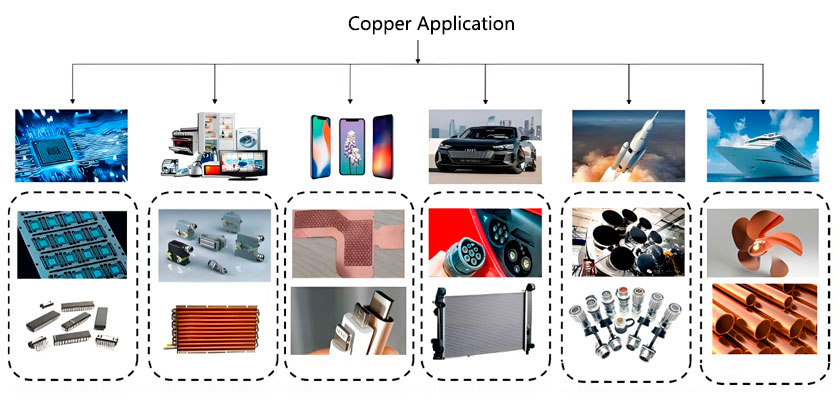

Copper, as a common metal, has the characteristics of electrical conductivity, heat conductivity, and wear resistance. It can often be seen in daily life, such as cables for power supply, copper faucets, water pipes, radiators, etc. It has made significant contributions to the development of human society and is widely used in various industries such as electronics, jewelry, machinery manufacturing, and construction. So do you know how copper is mined? Below, Xingaonai Heavy Industry will take you to learn about the mining methods of copper mines in detail.

The copper mining process mainly includes several main steps: exploration, mining, ore dressing and smelting.

1. Exploration

Exploration is the first step in copper mining and one of the most important links. Exploration refers to the survey of copper mining areas through geophysical, geochemical, geological and other means. Its purpose is to determine the distribution and form of the ore body, including geological landforms, lithology and structure. Use physical exploration and remote sensing technology to further identify the ore body shape, scale and occurrence. According to the exploration results, formulate a general plan for mine mining, including mining years, production capacity and equipment selection, and design safety measures and environmental protection plans.

2. Mining

After the location of the deposit is determined, the mining stage begins, which is mainly open-pit and underground mining. From the current situation of copper mining, open-pit mining accounts for a higher proportion than underground mining. According to the depth and scale of the ore body, choose open-pit or underground mining.

Underground mining method: It is mainly suitable for copper deposits buried deep underground. Generally, four methods are adopted: flat hole development, vertical shaft development, combined development and inclined shaft. Its characteristics are that it can protect the surface environment and reduce the distance of ore transportation, but the cost is high and requires a lot of manpower and material investment.

Open-pit mining method: It is the lowest cost and most efficient method in copper deposit mining. It is suitable for surface copper deposits and is mined using excavators, loaders and other equipment. Its characteristics are fast mining speed and large-scale collection of ore, but it will have a certain impact on the environment.

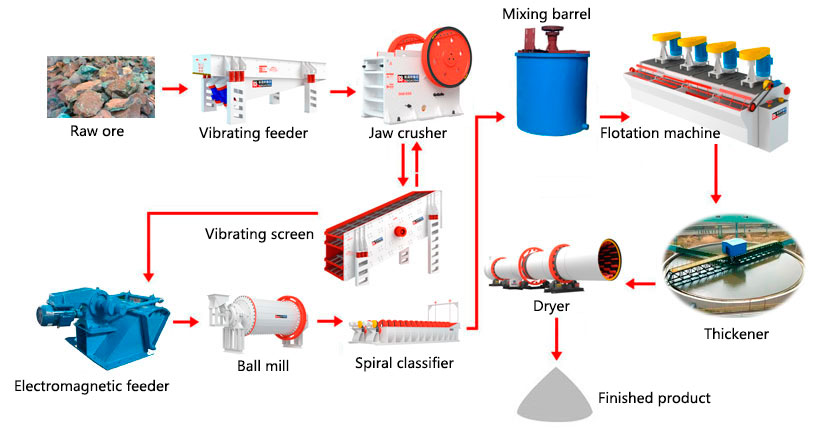

3. Ore dressing

Specific process of ore dressing: First, the copper ore is preliminarily crushed, and the vibrating feeder sends the material into the jaw crusher, and then the fine crusher is used for re-crushing. The copper ore materials that meet the requirements must be sent to the silo through the feeding device for grinding. The fine copper ore is fed into the ball mill through the feeding device for grinding, and then the ground copper ore is fed into the spiral classifier for washing and classification, and then sent to the flotation machine through the mixing barrel for flotation operation. The flotation operation mainly separates the required minerals from other minerals. The moisture of the material must be removed by a high-yield concentrator, and the copper ore raw materials required for production can be obtained by drying in a dryer.

4. Smelting

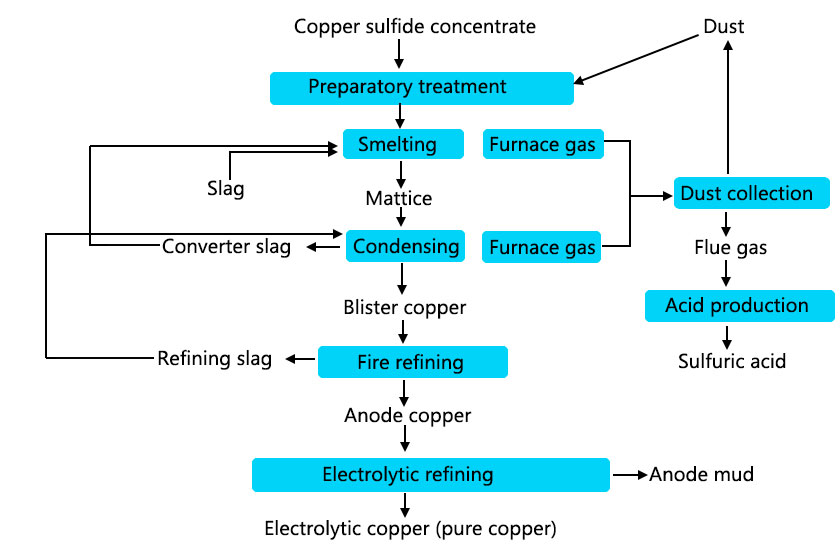

Pyrometallurgical copper smelting

Pyrometallurgical copper smelting is to melt copper ore and flux together at high temperature, first smelting into matte and then into crude copper or directly into crude copper. Except for some operations, this method is carried out at high temperature. Pyrometallurgical copper smelting can be carried out in various different equipment, such as blast furnace, reverberatory furnace, electric furnace, flash furnace and continuous copper smelting furnace. After smelting into matte, it is blown, pyrometallurgical refining and electrolytic refining to finally obtain electrolytic copper.

Advantages: high productivity, low energy consumption, good quality of electrolytic copper, conducive to the recovery of rare and precious metals, and wide range of applications.

Disadvantages: It causes serious air pollution and cannot directly process lean ore.

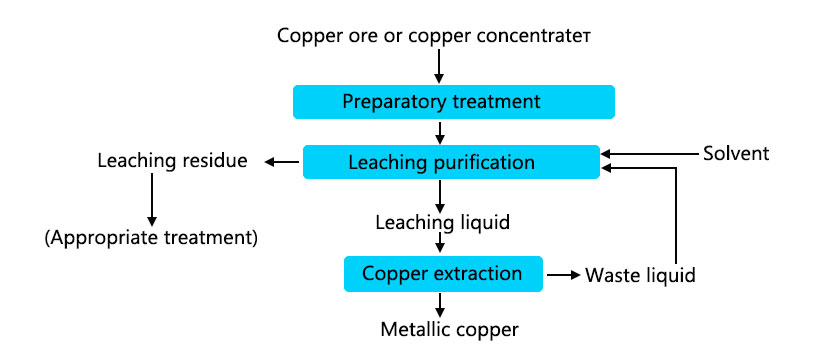

Hydrometallurgy

Hydrometallurgy is mainly used to process copper oxide ores, and is also used to process copper sulfide ores. Hydrometallurgy is to use solvents to smelt copper at room temperature, normal pressure or high pressure.

Currently, about 15% of the world's copper production is produced by the hydrometallurgical method, and its application range is not as wide as that of the pyrometallurgical method. Under normal circumstances, it is difficult to leach sulfide ores with cheap copper, the solvent corrodes the equipment, and the solid-liquid separation is difficult.

Author:[Xingaonai] Report this page